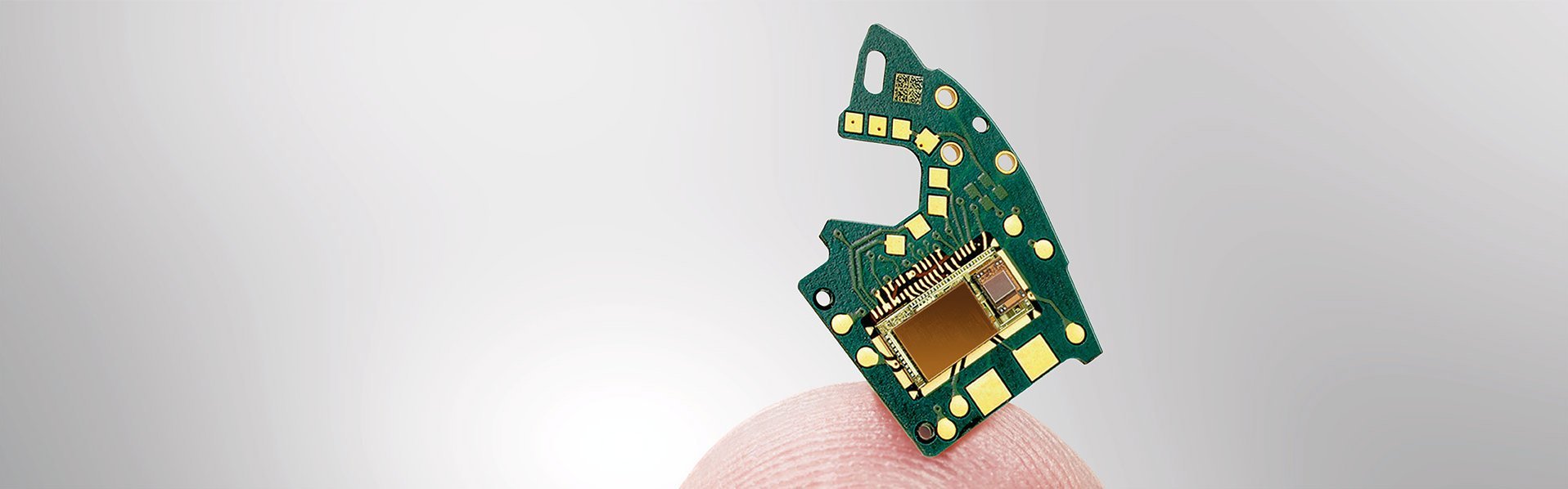

Laser Drilling of Circuit Boards

We create vias and blind vias on sophisticated printed circuit boards

Laser Drilling of Microvias

High density interconnect (HDI) technology requires connection holes with diameters of at least 50 μm. Microvias can be laser-drilled in RCC, FR4, FR5, Teflon®, and Thermount® materials.

When drilling is performed with the UV laser, both the top copper layer as well as the epoxy resin and fiberglass substrates are pierced in one operation. The laser energy is controlled so precisely here that the lower trace layer is only slightly roughened and at the same time cleaned. In contrast to CO2 and hybrid laser systems, LaserMicronics requires neither an upstream etching process nor a second laser.

UV laser processing offers short, nanosecond-range pulse widths that result in high peak pulse powers. The laser process thus guarantees a very good hole quality and a high throughput.

Advantages of UV Laser Drilling

- Drilling possible in various materials, such as RCC, FR4, FR5, Teflon®, and Thermount®

- No delamination and reduced “red ring effect”

- Automatic position and warpage correction through registration of fiducial marks and online scaling

- High precision and positional accuracy of drilled holes

- Ideal hole geometry