Processing of Ceramics

The laser: The perfect tool for processing hardened and brittle substrates

Microprocessing of Ceramics

Due to their outstanding electrical, mechanical, and thermal characteristics, ceramics are increasingly being used in the production of printed circuit boards and electronic components.

In this connection, laser processing facilitates production of complex geometries and guarantees maximum dimensional stability, edge quality, and throughput.

The following ceramic materials can be processed:

- Silicon nitride (Si3N4)

- Aluminum oxide (Al2O3)

- Aluminum nitride (AlN)

- Zirconium oxide (ZrO2)

- LTCC (low temperature co-fired ceramics)

- Composite ceramic materials

Laser processing of ceramics - the possibilities

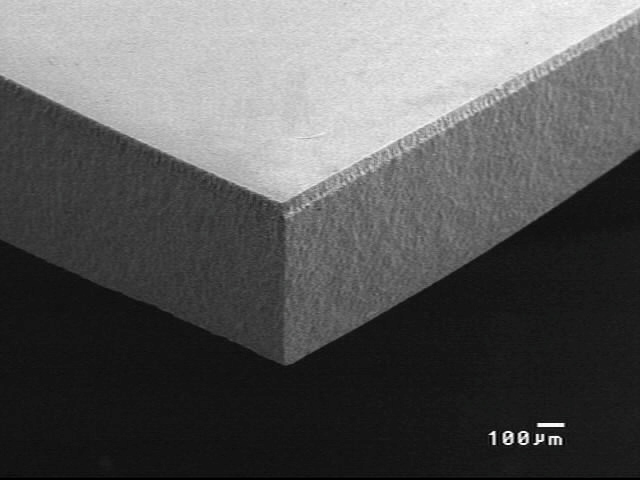

Laser Cutting of Ceramics

In laser cutting of ceramics, a continuous kerf is created, e.g., as an opening, contour cut, or hole.

Laser Drilling of Ceramics

Laser drilling of ceramics allows production of the smallest hole diameters (for example, <75 μm in LTCC with high aspect ratios). The main features of the processing are ultrafine structures and high-quality edge structures.

Laser Scribing of Ceramics

In laser scribing, a 20–50 μm deep kerf is first cut in the ceramic material. The scribing depth can be precisely controlled through adjustment of the laser focus. Then the material is broken along this line. Laser scribing allows clean separation of segments with high quality and accuracy.

Advantages of Laser Microprocessing

In contrast to mechanical processing, laser processing of ceramics does not result in microcracks in the material. Because only a small amount of material is vaporized, the laser works with very high scribing speeds of up to 100 mm/s without damaging the material.

- High edge squareness

- Low edge roughness

- No formation of microcracks

- Holes <75 μm with high aspect ratios possible

- Minimal thermal effects through optimized UV processing

- Noncontact material processing, so no material warpage

- High precision and positional accuracy of cut edges through automatic registration